Selective Solder

What is Selective Solder? Why is it used?

Selective Solder is a replacement for legacy wave solder processes, where individual through hole components are soldered using a molten solder fountain tip. The tip moves around under the PCB and “touches” pins and pads needing solder. This process is used when parts can not be attached to a PCB due to mechanical or thermal limitations of the part.

Selective Solder is ideal for connectors, batteries and heatsinks.

Give us a call, or explore the case study below to see how Fleetwood Electronics uses Selective Solder technology.

Selective Solder Case Study

Our selective soldering capabilities in practice

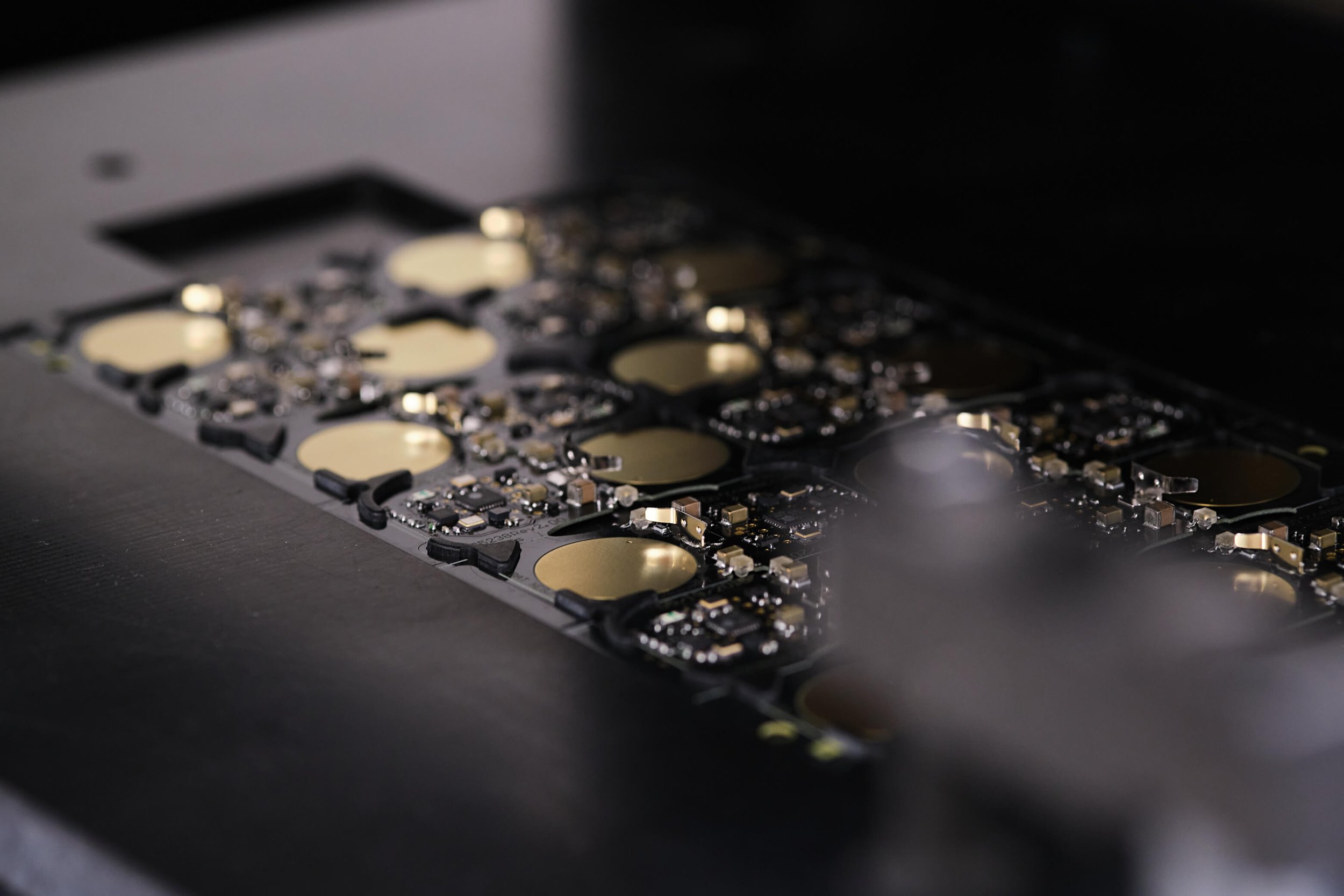

The photo to the right shows a battery operated temperature monitoring device operating from a lithium coin cell. Lithium coin cells are unable to withstand the heat profile of reflow associated with SMT processing.

To accomplish this project we utilized a selective solder secondary operation to attach the lithium coin cell.

This is a common application for selective solder, along with heatsinks, super capacitors, large connectors and large through hole components.

The photo above shows a battery operated temperature monitoring device operating from a lithium coin cell. Lithium coin cells are unable to withstand the heat profile of reflow associated with SMT processing.

To accomplish this project we utilized a selective solder secondary operation to attach the lithium coin cell.

This is a common application for selective solder, along with heatsinks, super capacitors, large connectors and large through hole components.

Have a similar need?

Complete the form or contact us directly to start a conversation.

Email: sales@fleetwoodelectronics.com

Phone: 616-820-8202